Exploring the Great Outdoors Why Every Adventurer Needs an Outdoor Watch

Exploring the Great Outdoors: Why Every Adventurer Needs an Outdoor Watch

Introduction: Embarking on outdoor adventures offers a sense of freedom and connection with nature that few other experiences can match. Whether you're hiking through rugged terrain, camping beneath the stars, or conquering mountain peaks, having the right gear is essential for a safe and enjoyable journey. One piece of equipment that every outdoor enthusiast should have in their arsenal is an outdoor watch. In this blog, we'll explore the reasons why an outdoor watch is a must-have companion for your next expedition into the wilderness.

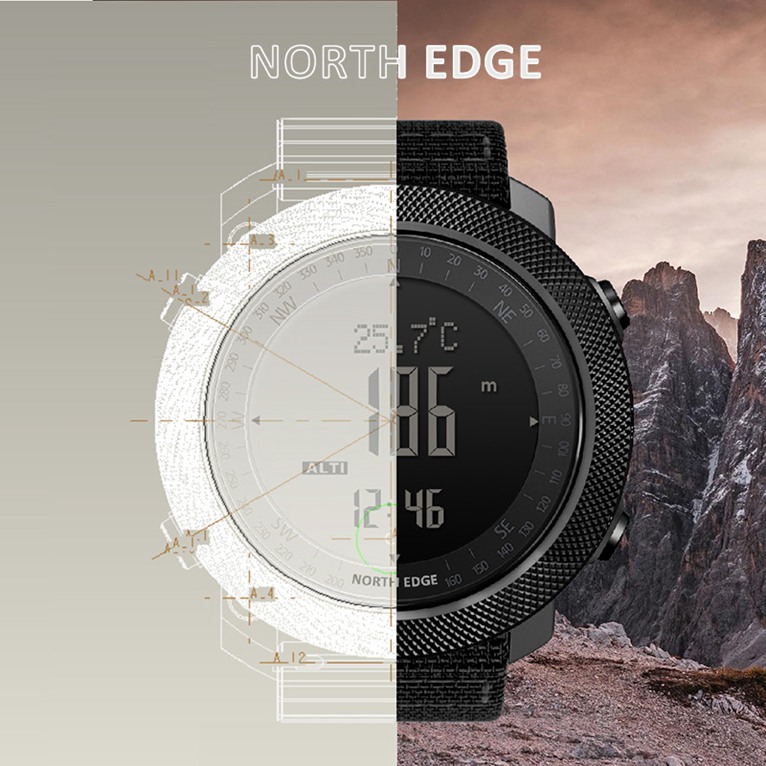

Section 1: Durability and Reliability When you're out in the wild, your gear needs to be able to withstand whatever Mother Nature throws its way. Outdoor watches are specifically designed to be rugged and durable, capable of handling the toughest conditions. With features like shock resistance, water resistance, and scratch-resistant materials, these watches can withstand the bumps, scrapes, and splashes that come with outdoor activities. Whether you're trekking through dense forests, scaling rocky cliffs, or navigating white-water rapids, an outdoor watch will be up to the challenge.

Section 2: Essential Outdoor Features In addition to being tough and durable, outdoor watches come equipped with a range of features designed to enhance your outdoor experience. These include built-in GPS for navigation, altimeters for tracking elevation, barometers for monitoring weather changes, and compasses for finding your way. Some models also include specialized functions such as tide graphs for surfers, moon phase calendars for stargazers, and fishing timers for anglers. With these features at your fingertips, you'll have all the information you need to stay safe and make the most of your outdoor adventures.

Section 3: Fitness and Activity Tracking Many outdoor watches also double as fitness trackers, allowing you to monitor your physical activity and performance while you're on the go. These watches can track metrics such as steps taken, distance traveled, calories burned, and heart rate, providing valuable insights into your overall health and fitness. Whether you're training for a marathon, monitoring your hiking progress, or simply trying to stay active, an outdoor watch can help you achieve your fitness goals and stay on track during your outdoor adventures.

Section 4: Versatility and Style In addition to their practical features, outdoor watches are also versatile accessories that can complement any outdoor enthusiast's wardrobe. With a wide range of styles, colors, and designs to choose from, you can find a watch that suits your personal taste and outdoor aesthetic. Whether you prefer a classic analog watch with a leather strap, a sleek digital watch with a silicone band, or a rugged GPS watch with a stainless steel bracelet, there's an outdoor watch out there to suit every style and preference.

Conclusion: From rugged durability to essential outdoor features, fitness tracking capabilities, and versatile style options, an outdoor watch is a must-have accessory for any adventurer. Whether you're exploring remote wilderness areas, tackling challenging outdoor activities, or simply enjoying nature's beauty, having a reliable and feature-packed watch on your wrist will enhance your outdoor experience and help you make the most of every moment spent in the great outdoors. So, before you embark on your next adventure, be sure to invest in an outdoor watch that will keep you prepared, informed, and stylish every step of the way.